WIPER SWITCH PROBLEMS

In the not so distant past I took my Mercedes Benz C180K for road worthy at one of the AVTS centers but it failed horribly. Not because the car was in a poor mechanical condition but rather that I needed to know exactly what was wrong with it, in order to fix it to at least roadworthy standards. So this was deliberate on my part but it cost me a good R500.00 but it was worth it. I also needed there to be a record on file that it had gone through the necessary checks. So there!

However, even though I was able to register the Merc C180K on my name, I couldn't get its licence disk because of some issue I had with City's Motor Vehicle Registration Offices regarding the licence for a Renault Megan. I had failed to draw its licence for almost 3 years. Since, the engine had given up the ghost and I kinda abandoned it. Anyway the issue I had, involved a 12% monthly penalty fee added to the principal amount including interest. It turned out to be a ridiculous about of money. But that's a story for another day. The image below gives you an idea of what was wrong with the Mercedes Benz C180K. A total of 13 issues that needed sorting.

I intend to cover item 1&2 on the list and give you a rundown on its processes and procedures. As can be seen the rear wiper blade was torn which needed replacement. My personal opinion is that the examiner was being petty because the rear wiper worked and wiped away water off the rear screen just fine but had a 2cm piece at the end of the wiper blade that was delayed and dancing about. Be that as it may, it compelled me to replace it, as can be seen below.

I bought three Hella wiper blades, from their Cleantech range which are definitely not as good as the original Mercedes Benz wiper blades but a far cry cheaper. Buying cheaper certainly doesn't mean better because I ended up with a handful of plastic parts which was of no use to me. I only needed two pieces for the front wipers, as came be seen in the image below. Fitting the front wipers was a basic clip-on whereas the rear wiper needed a 10mm spanner to remove the old and replace the new.

Next on the list is the "front wiper not working". As far as I was concerned they worked on the intermittent setting, but as far as the anal examiner was concerned, the front wiper wasn't working at all. When the push button on the indicator stalk was pressed it worked just fine for two wipes. But it also meant that it has to be pressed continually during rainy weather to keep the windscreen clear. But I'm not going to complain any further, and decided to repair the problem. To get to the indicator/wiper stalk assembly, I needed to remove the air bag, the steering wheel and the steering wheel hub.

NB! Before even thinking of removing the air bag, it is mandatory to remove the negative battery terminal then the positive then wrap each terminal in a cloth to prevent them from accidentally making contact with the battery terminals whist you busy with the airbag. Alternatively just remove the battery. Failure to do so could cause the airbag to deploy whist removing it, and it may cause severe injury to your hands and face.

So this is what I started out with. Behind the steering wheel, there two holes with a torx screw in each. Loosening them both allows you to remove the airbag but please don't pull the airbag off, because the wires are actually fairly short and fragile. Flip the airbag over and remove all three plugs as can be seen below. The plugs have anti slip-out locks, so fist unlock them and remove the plugs carefully.

Next the steering wheel needs to be removed. It is held onto the splined steering column shaft with a single countersunk screw. To remove it you would need a hex allen socket with a power-bar. This screw will have to be re-torked on re-assembly. I don't have one so I made a mark on the steering where the power-bar touched its outer rim and re-tightened it to the same position but added a few drops of locktight liquid to the screw.

Now that the steering is ready to be pulled off the splined shaft, notice that I've made two black pen marks on the splined steering column shaft that coincides with the key slots in the steering wheel. This is to ensure that the steering wheel gets replaced in exactly the same position. Failure to do so, will cause you to end up with an offset horizontal axis.

Now that the steering is out of the way, the steering wheel hub is clearly visible. The most important thing to look at in the image below is the visible torx screw head. See that it is exactly in the centre of the hole. The next image will show that I've moved the top ring of the hub ever so slightly to demonstrate that is moves even though it shouldn't be allowed to. The hub will ensure that the steering wheel returns to the correct position after going around a corner as it determines the direction of the front wheels. See the two relief diagrams on either side of the triangle. It represents the car with its four wheel, its front to at 45 degrees angle.

Notice that I've inserted my torx key into the slotted hole below. This lines up all three screws so that two pieces of tape can be pasted on the top movable part of the hub and its side. Once this is done, the three screws can be removed. Also notice the arrow head below the triangle lines up with the two black marks on the splined shaft.

Here all three screws are visible inside the holes. Ensure on re-assembly that they stay in this position. Refer to the images above to make sure they stay that way. After the screws are removed the hub can be lifted vertically off the shaft. The image below exposes the wiper and the speedo-cruise mechanisms. The speedo-cruise mechanism isn't held down by screws and also just lifts out. be careful not to loose the two plastic slides that sits directly above both the wiper and speedo-cruise stalks.

Now that the speed-cruise unit is removed, the screw on the right side on the opposite side from where the stalk protrudes. As can be seen below, the torx key is pushed through a hole in the plastic housing from the bottom, to undo the clamp screw. And the next image shows the screw almost totally removed. Thereafter the entire unit along with its plastic housing can be lifted off the steering column shaft.

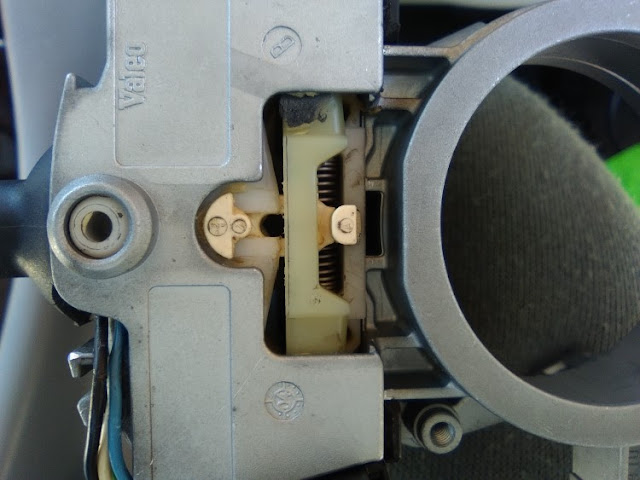

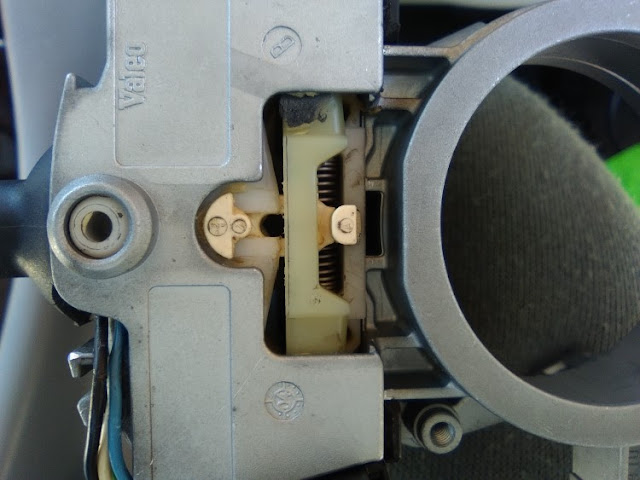

This is what all the fuss was about, getting to the wiper switch. The image below shows the underside of the housing and the three visible screws than needs to be removed to get the switch mechanism out of the housing.

The image below is the reason why everything had to be taken apart. So you can either replace or repair the Mercedes Benz combination indicator light wiper switches assembly assembly which costs well over R3500.00. The only problem is that the blue wire broke off. In fact the blue wiper wire was cut by the sharp edge of the black wiper stalk at the point where the wires go into it. I believe this is a fairly common problem and that Mercedes Benz has somewhat modified the wiper stalk in later models to prevent the blue wire from being cut.

As can be seen, I just didn't solder the broken wire back together again. I extended it with a 2cm length of wire to prevent it from pulling light. By so doing provided some play in the blue wire for movement.

The switch assembly fully assembled, ready to go back into its housing.

What you may notice on the above pic is that a filed away a piece of the wiper stalk exactly where the four wire enter into into it. The sharp edge of the black wiper stalk is what cut the blue wire in the first place.

Make sure the cream slide which moves to two different position when the indicator stalk is move up or down. Failure to see that it moves correctly when the wiper stalk is move may need you to disassemble and redo it.

Assembly is the reverse of disassembly. It's a good idea to take photographs of every step just in case you forget the assembly process then you can at least revert to those pics.

Assembly is the reverse of disassembly. It's a good idea to take photographs of every step just in case you forget the assembly process then you can at least revert to those pics.

Once everything is back together, the wiper turn switch at the end of the wiper stalk should work seamlessly. Do not reconnect the battery to test its functionality mid-job. Fully assembly before the battery is reconnected. It would prevent the airbag from popping, or leave you with a dash board airbag lite that won't go off.